industry 4.0, also known as the forth industrial revolution, describes the last trend of industrial automation: communication among productive systems and process real time adaptation based on advanced big data analysis.

Recent market analysis demonstrate that manufacturing factories that want to remain competitive on a global scale have to invest and adopt industry 4.0 technology.

Italy has a specific incentive plan reserved for company that want to renew their machines with industry 4.0 technology. Most of other states have it as well.

S.E.I. srl can lead your company in this innovation process, analyzing the current production plan and machines, choosing the best technology for your specific application, designing and implementing ad-hoc solutions tailored to improve your manufacturing process.

S.E.I. srl has a wide range expertise in the manufacturing sector: iron and steel, automotive, textile, pulp and paper, plastic and chemistry industry are example where S.E.I. srl can apply its expertise helping your company to grow and stay on top of the current innovation.

S.E.I. srl has a long standing and a wide range of experience in the industrial automation industry.

Our company offers products that can be coordinated with and adapted to any given project, allowing us to provide custom solutions and efficient customer service by our highly specialised technicians.

PRESSES

S.E.I. operates in the metal forming sector with safety applications designed to protect people and machinery.

TEXTILE

Management and control of plants for calenders, padding machines, winding units, doubling machines and customer-specific special machinery.

PLASTIC

S.E.I. has over 20 years of experience in the management and supervision of extrusion lines, moulding, temperature control lines, mixing plants and wire lines.

Lifting equipment

S.E.I. has long-standing experience in the automation and control of lifting systems: gantry cranes, bridge cranes, suspension cranes, wheeled cranes and special cranes.

PACKAGING

In the packaging industry, S.E.I. offers its experience in the development of innovative solutions for switchboards and systems, as well as commissioning sophisticated mechanized lines.

METALWORKING

S.E.I. provides management, control and supervision systems for rolling plants, cutting lines, section bars, wire drawing, combination dies, pulling benches, sanders, winders, coiling machines, tippers, bending machines, straighteners, cut-to-length shears, strand lines, stranding machines, automatic magazines, twisting machines.

LOW AND MEDIUM VOLTAGE

Design, installation and maintenance of LV-MV substations in accordance with the third edition of CEI 0-16, adaptation for AEEG resolution 84/2012/R/eel, oil or resin transformers, distribution boards, power centres and motor control centres.

OIL & GAS

S.E.I. offers automated and project integration solutions and services to the oil and gas industry, including the plant design, engineering, procurement, construction and commissioning.

WATER TREATMENT

Design of water pumping and distribution stations, boring and provision of submersible pumps, assistance and installation, water potabilization plants with remote management.

GENERATORS

Supply of generators from 1 to 2500 KVA in soundproof, open-set or base versions and in containers complete with automatic change over from main supply to generator and vice versa.

POWER DISTRIBUTION

Medium voltage systems (which, besides the cables, includes accessories and components) for hooking up industrial and/or residential buildings to the primary distribution lines and low voltage systems for the distribution of electrical energy and the wiring of buildings.

PAPER MAKING AND CONVERTING INDUSTRY

Automation of production lines for corrugated cardboard, laminating and cutting lines, winding and rewinding machines, coaters, calenders; complete plants for paper mills.

BUILDING AUTOMATION

Management and control of all types of smart buildings (industrial, commercial or residential): lights, heating, ventilation, access security, energy management, etc.

Copper and fibre optic cabling systems, networking and internetworking systems.

STABILISERS

In addition to the standard production, S.E.I. develops and manufactures 1 to 4000 KVA single-phase and tri-phase electrodynamic and static LV-MV stabilisers which are microprocessor controlled.

RAILWAYS

Design and manufacture of electrical panels, signal and power wiring, automation and monitoring systems for power and lighting installations on high speed routes.

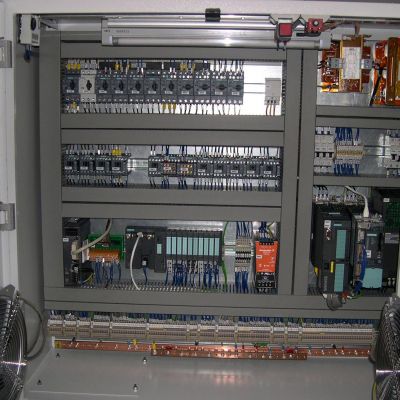

S.E.I.’s staff develops and designs solutions for the automation of machinery and process control for plants.

Working closely with the customer’s technicians, S.E.I. engineers create the functional specifications and the P&I diagram for the process, assist in selecting the equipment, the monitoring systems and the measuring instruments for field signals.

Our top priority is to deliver the best value for money whilst ensuring that the products are readily available on the international market i.e. constructing standard systems customised by engineering.

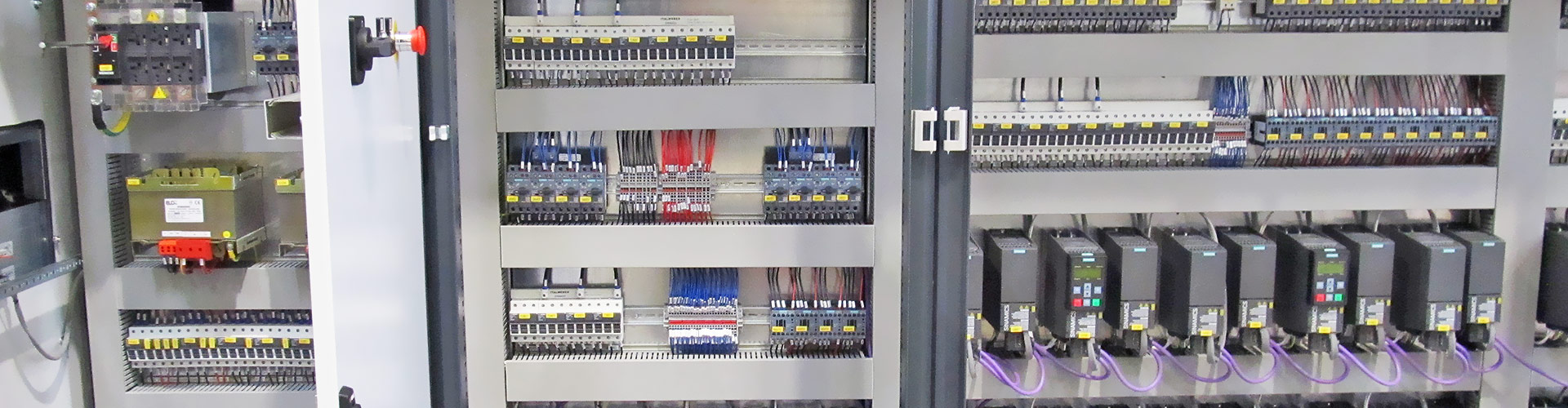

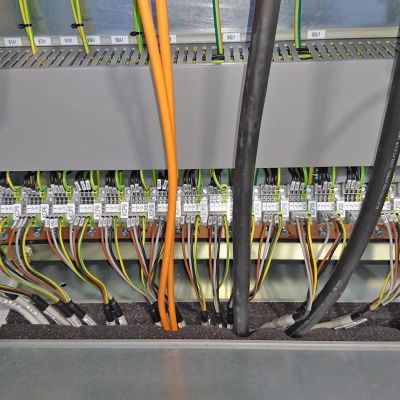

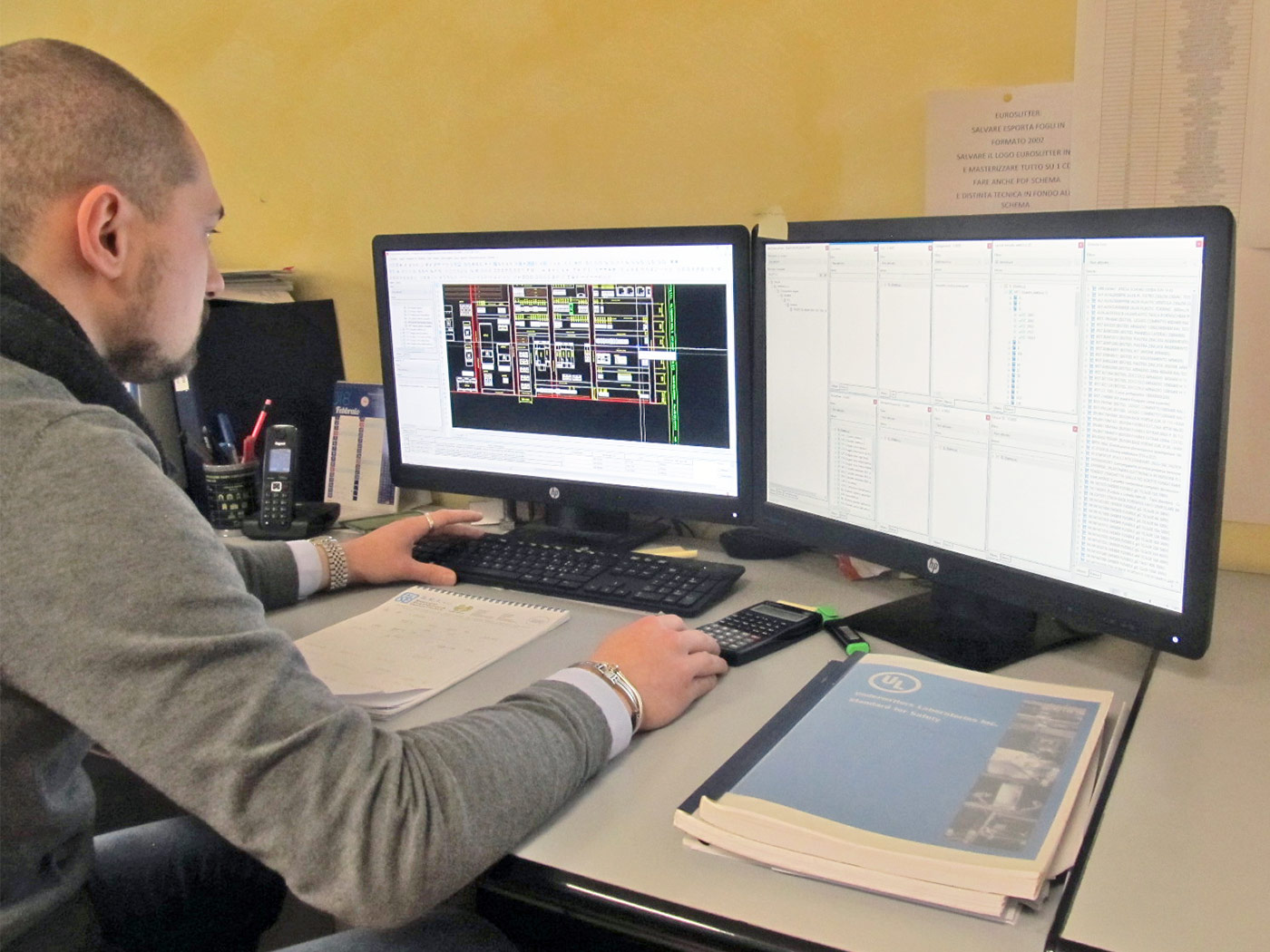

Electrical design

The electrical design is developed in-house, aided by workstations equipped with different types of software such as: AUTOCAD (Betacad), ELCAD, EPLAN P8, etc.

Our engineers, based on a detailed customer needs analysis, plot out the specifications to be used in developing the hardware project.

All documentation is produced according to norme IEC 60204-1, IEC 750, EN 50.00XX, UL508A standards along with any customer-specific standards.

S.E.I s.r.l. has passed the stringent requirements to obtain the authorization to mark electrical equipment, for industrial control machines, made for the North American market (USA and Canada) with the UL, CUL and CULUS marks.

These marks can be applied on electrical panels, junction boxes, pulpits, lecterns, consoles and everything that may be necessary for the management and control of machinery for industrial automation.

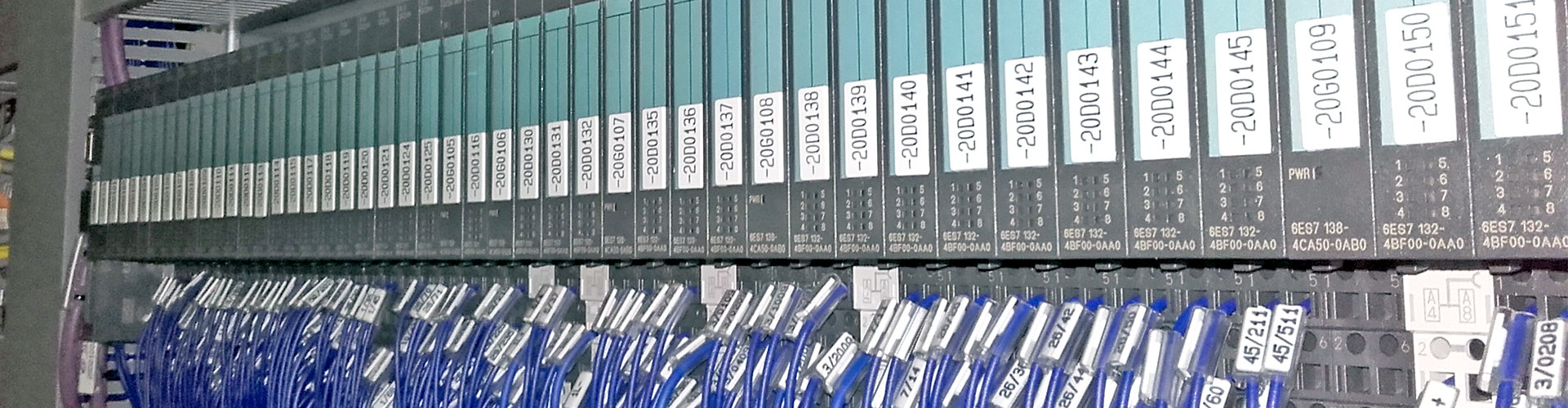

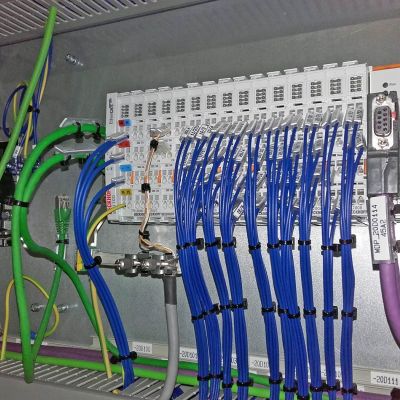

PLC software design

The PLC design department is staffed by a number of senior technicians. The company has chosen to be integrators which has allowed it to broaden its experience in a diverse range of equipment.

PLC software is developed in extremely complex configurations and different types of motor controls are used: brushless, direct current (DC) or vectoral alternating current (AC).

We have completed projects using PLCs made by Siemens, Allen-Bradley, Schneider, Omron and ABB; motion controllers, axis interpolation, PID controllers, numerical controls, serial communication boards, Modbus communication boards, load-cells interface cards are used in each of these PLCs.

We have created communication drivers between PLCs and dedicated equipment.

For some customers, with very complex applications, network architectures were developed between the PLC and computer using: industrial ethernet, Profibus, Controlnet (Allen-Bradley), up to double-digit nodes, all aimed at achieving full factory automation control.

All programs are created in accordance with IEC 1131-3 (CEI EN61131-3) and customer-specific standards.

PC software design

S.E.I.’s team also includes information system designers who handle the monitoring systems.

The basic function of a monitoring system is the human machine interface (MMI, HMI) so as to be able to achieve the full potential of computers.

Keeping in pace with the latest technical innovations, S.E.I. is able to provide both complete projects and specific software making it possible to achieve greater integration across industrial IT systems. The range of SCADA systems (Supervisory Control and Data Acquisition), production tracking, statistical analysis and data exchange with higher management levels is geared toward the identification, by the customer, of increasingly efficient business control strategies.

PC programs for supervisory systems are developed using SCADA packages such as WINCC, TIA PORTAL, FACTORYLINK, INTELLUTION, IFIX, SWMAKER, and programming languages such as Visual Basic.

All programs are made in accordance with IEC and customer-specific standards.