Design

S.E.I.’s staff develops and designs solutions for the automation of machinery and process control for plants.

Working closely with the customer’s technicians, S.E.I. engineers create the functional specifications and the P&I diagram for the process, assist in selecting the equipment, the monitoring systems and the measuring instruments for field signals.

Our top priority is to deliver the best value for money whilst ensuring that the products are readily available on the international market i.e. constructing standard systems customised by engineering.

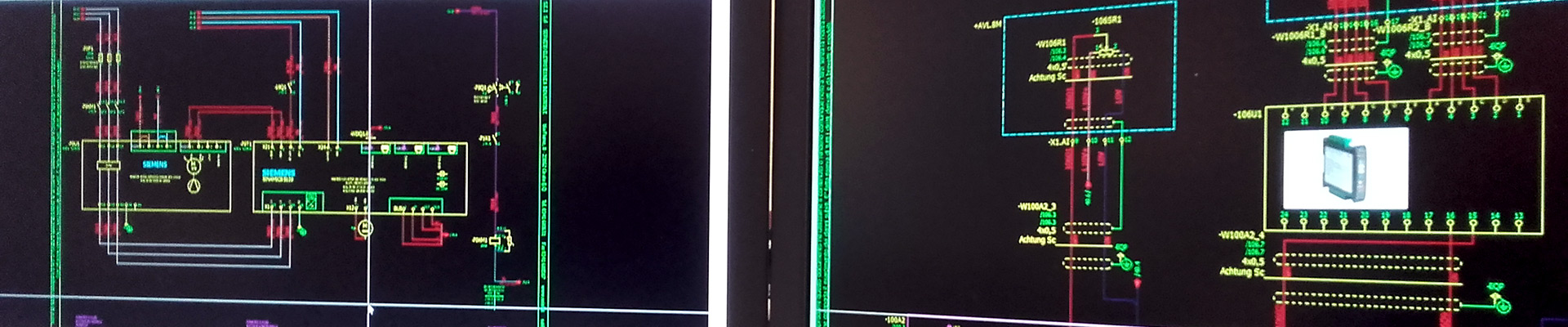

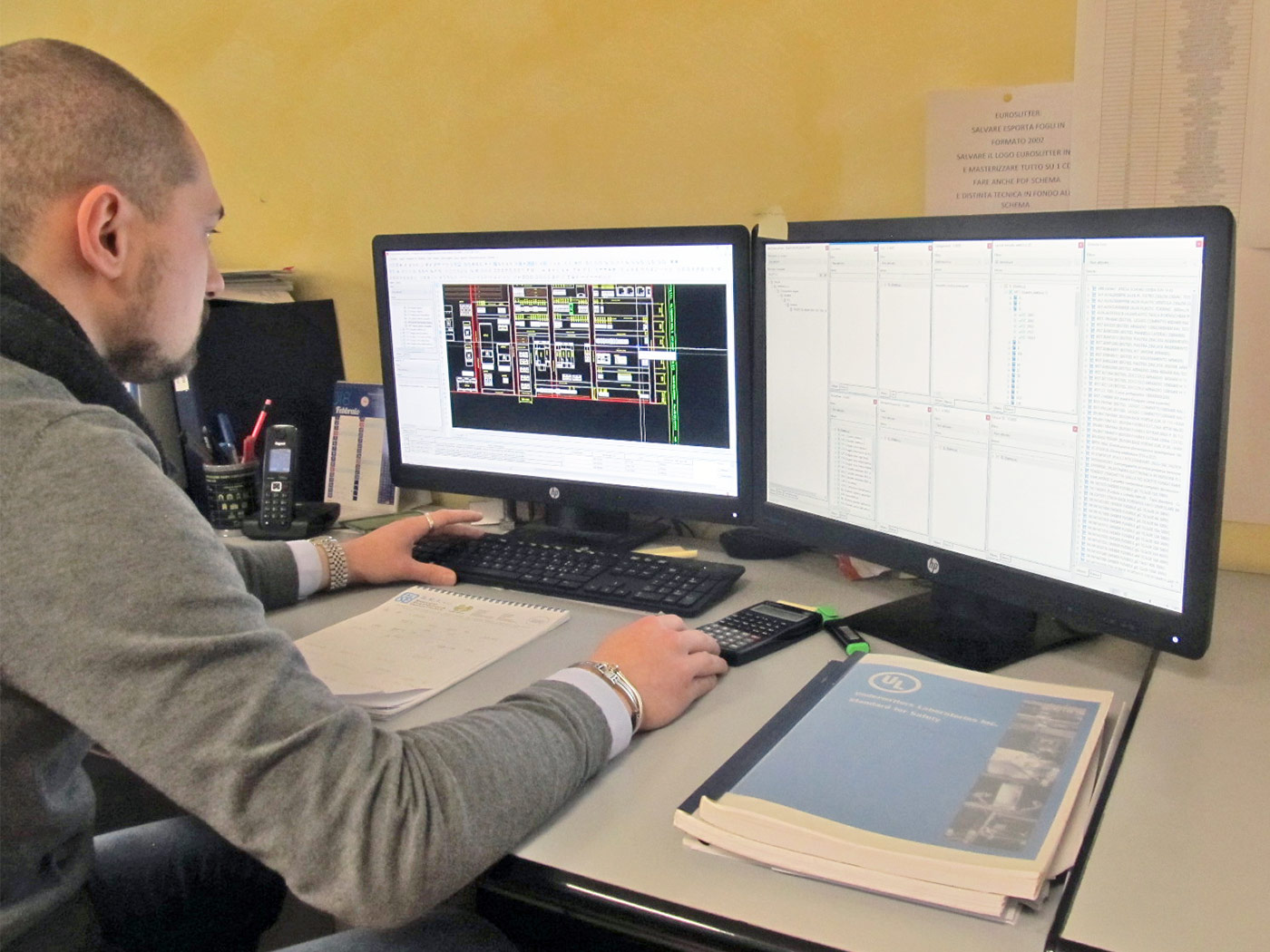

Electrical design

The electrical design is developed in-house, aided by workstations equipped with different types of software such as: AUTOCAD (Betacad), ELCAD, EPLAN P8, etc.

Our engineers, based on a detailed customer needs analysis, plot out the specifications to be used in developing the hardware project.

All documentation is produced according to norme IEC 60204-1, IEC 750, EN 50.00XX, UL508A standards along with any customer-specific standards.

S.E.I s.r.l. has passed the stringent requirements to obtain the authorization to mark electrical equipment, for industrial control machines, made for the North American market (USA and Canada) with the UL, CUL and CULUS marks.

These marks can be applied on electrical panels, junction boxes, pulpits, lecterns, consoles and everything that may be necessary for the management and control of machinery for industrial automation.

PLC software design

The PLC design department is staffed by a number of senior technicians. The company has chosen to be integrators which has allowed it to broaden its experience in a diverse range of equipment.

PLC software is developed in extremely complex configurations and different types of motor controls are used: brushless, direct current (DC) or vectoral alternating current (AC).

We have completed projects using PLCs made by Siemens, Allen-Bradley, Schneider, Omron and ABB; motion controllers, axis interpolation, PID controllers, numerical controls, serial communication boards, Modbus communication boards, load-cells interface cards are used in each of these PLCs.

We have created communication drivers between PLCs and dedicated equipment.

For some customers, with very complex applications, network architectures were developed between the PLC and computer using: industrial ethernet, Profibus, Controlnet (Allen-Bradley), up to double-digit nodes, all aimed at achieving full factory automation control.

All programs are created in accordance with IEC 1131-3 (CEI EN61131-3) and customer-specific standards.

PC software design

S.E.I.’s team also includes information system designers who handle the monitoring systems.

The basic function of a monitoring system is the human machine interface (MMI, HMI) so as to be able to achieve the full potential of computers.

Keeping in pace with the latest technical innovations, S.E.I. is able to provide both complete projects and specific software making it possible to achieve greater integration across industrial IT systems. The range of SCADA systems (Supervisory Control and Data Acquisition), production tracking, statistical analysis and data exchange with higher management levels is geared toward the identification, by the customer, of increasingly efficient business control strategies.

PC programs for supervisory systems are developed using SCADA packages such as WINCC, TIA PORTAL, FACTORYLINK, INTELLUTION, IFIX, SWMAKER, and programming languages such as Visual Basic.

All programs are made in accordance with IEC and customer-specific standards.